Working principle of automobile PCB control board Sealed micro switch

The working principle of the Sealed micro switch on the automobile PCB control board is similar to that of the general Sealed micro switch, but its specific application may vary depending on the control board design and vehicle system. Sealed Micro switches can be used in car window control systems and installed near window switches or electric window controllers to monitor the opening and closing status of windows.

In the vehicle’s central locking control system, a microswitch may be installed at the central locking button or remote control to monitor the opening and closing of the central locking. Micro switches may also be used to monitor the status of other vehicle interior buttons and switches, such as air conditioning buttons, light switches, etc. Control buttons and switches on the dashboard may use microswitches for status monitoring to trigger corresponding vehicle control operations.

-

Installation of control panel position

Sealed Micro switches are usually installed at specific locations on the car’s PCB control board. This location is usually associated with the vehicle component or system that needs to be monitored. A microswitch may be installed at the location of the door lock or switch to monitor the opening and closing status of the door. This helps the vehicle system determine whether the door is safely closed and trigger appropriate warnings or actions. A Sealed micro switch can be installed near the hood lock system to detect the open and closed status of the hood. This helps ensure the hood remains closed while driving to prevent safety issues.

-

Sealed Micro switch contact design

A Sealed microswitch has a mechanical contact inside it, usually spring-loaded, that switches when triggered. The design of this contact determines the closed and open states of the micro switch. Contacts are usually made of conductive material to ensure good electrical conduction. Commonly used materials include copper alloys or copper-tin alloys. These materials have excellent electrical conductivity and corrosion resistance.

The contacts of a Sealed micro switch are usually spring-loaded so that when the triggering condition disappears, the spring can return the contacts to their original position. The spring needs to be designed with longevity and stability in mind to ensure long-term reliability of the switch. The triggering force of a contact refers to the force that needs to be applied before the switch is triggered. The design needs to ensure that the triggering force is moderate, which can prevent misoperation and enable easy triggering under normal operation.

The contacts need to maintain good contact stability when in the closed state to ensure stable conduction of the circuit. The surface of the contacts is usually treated with gold plating to improve contact performance. The contacts should be designed to ensure moderate switching speeds. Switching too quickly can cause premature wear of the contacts, while switching too slowly can cause circuit instability.

-

Circuit connection

The Sealed micro switch is connected to the PCB control board through welding or other electrical connection methods. Its contacts are connected to the circuit on the control board. Micro switches are usually connected to the PCB control board by soldering. Soldering is a reliable connection method that ensures smooth flow of electricity through contacts and other components on the PCB.

Sealed Micro switches usually have two or more pins, one of which is normally closed and the other is normally open. These pins are used to connect the circuit, the normally closed pin is usually open when the switch is triggered, and the normally open pin is closed when the switch is triggered. There need to be corresponding circuit paths on the PCB to ensure that the pins of the microswitch can be connected correctly to the rest of the control board. This may involve the design of wires, interlayer connections of circuit boards, etc.

The pins of the Sealed micro switch connect to circuitry on the control board, which may be connected to other electronic systems in the vehicle for specific functions or controls. The connected circuit should take safety and stability into consideration. Ensure that the electrical connections in the circuit are stable and not easily affected by environmental factors such as vibration, humidity, etc.

-

Status monitoring

The status of the Sealed micro switch on the automobile PCB control board is monitored, and the opening and closing status of the circuit is usually detected through electronic components such as resistors and capacitors. The status of a microswitch indicates the status of a specific vehicle component or system. Considering the harsh conditions of the automotive environment, circuit connections require a certain protective design to prevent dust, moisture and other factors from affecting the stability of the connection.

On automobile PCB control boards, micro switches are often used for status monitoring to detect status changes of specific vehicle components or systems. The status monitoring of micro switches plays a key role in the vehicle’s electronic control system. The electronic control system monitors the status changes of the micro switches and triggers corresponding responses as needed. For example, if a microswitch is used to detect the status of a car door, the status change may trigger a warning that the door is not closed.

The status of micro switches is usually continuously monitored to reflect status changes of vehicle components or systems in real time. This helps ensure that the vehicle is in a safe condition while driving and parking.

-

System response

According to the status of the micro switch, the electronic control system on the PCB control board can take corresponding measures. For example, if a microswitch detects that a certain component needs to be operated or the vehicle requires specific control, the circuit on the control board may trigger the corresponding operating command. In some cases, the status information of the microswitch may be related to the vehicle’s safety system. For example, if a microswitch is used to monitor the status of a car door, the system may trigger a warning that the door is not closed to ensure that the vehicle is in a safe state while driving.

How can micro switches improve the performance of automotive PCB control boards?

The performance of the micro switch on the automobile PCB control board is directly related to the reliability and stability of the entire vehicle’s electronic system. Choose high-quality micro switches with good materials and design to ensure reliability and long life. Durability is particularly important for automotive PCB control boards because the vehicle may be affected by environmental factors such as vibration and temperature changes during operation.

Make sure that the design of the micro switch takes into account the special environment of the car, such as dust resistance, water resistance, high temperature resistance and low temperature resistance. This helps maintain the stability of the microswitch under a variety of conditions. The design of the micro switch should ensure precise triggering and reset to prevent misoperation. This is very important for systems that require highly precise control.

Select a microswitch that meets the electrical performance requirements to ensure that it has a stable electrical connection in the closed and open states. This helps prevent electrical problems such as shorts or opens. Considering the application of micro switches in safety systems, ensure that their design complies with relevant safety standards and regulations. This includes safety-critical applications such as door locks, hood locks, braking systems and more.

The design of the micro switch should be easy to integrate on the automotive PCB control board. This includes proper pin design, connection methods, and interoperability with other components. Some micro switches have status monitoring and feedback functions and can report their status in real time. This helps the vehicle system monitor the working status of the micro switch and take appropriate measures in a timely manner.

In some critical systems, such as braking systems or driver assistance systems, it is important to prevent false triggering of microswitches. The design takes into account the mechanism to avoid false triggering. By selecting the appropriate microswitch and considering its environmental adaptability and working characteristics, the performance of the automotive PCB control board can be effectively improved. This helps ensure the reliability, stability and safety of vehicle electronic systems.

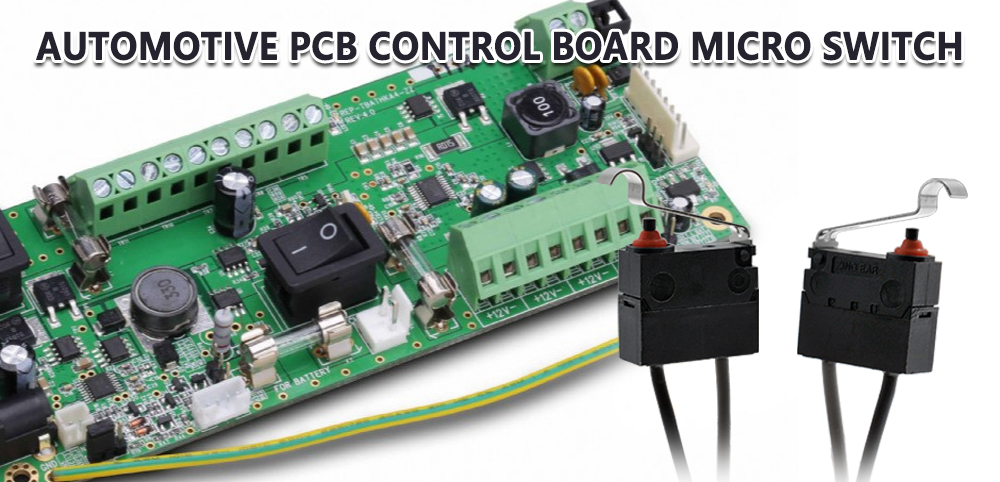

Overview of automobile PCB control board micro switch

The micro switch on the car PCB control board is an electronic component used to monitor and control vehicle systems. An overview of micro switches includes their basic structure, working principle and application scenarios. A microswitch is a small electronic switching device, usually consisting of a mechanical contact and a spring connected to it. The contacts are designed so that the circuit can be opened and closed under the influence of external force (usually pressing or releasing a button), thereby triggering the relevant electronic control.

The working principle of the micro switch is based on the opening and closing of mechanical contacts. When the micro switch is in a non-triggered state, the contacts are closed, current can flow, and the circuit is in a path state. Once the triggering conditions are met, the mechanical contacts open, interrupting the current flow and the circuit becomes an open circuit.

The microswitch on the automobile PCB control board is a key component in the vehicle electronic system. It provides safety, convenience and reliability to the vehicle by monitoring and controlling the status of different components.

On automobile PCB control boards, micro switches are widely used in the control of multiple systems and components. Common application scenarios include:

Door lock system: Used to detect whether the door is fully closed to trigger the central locking system.

Hood lock system: Used to monitor the status of the hood to ensure that the hood is safely closed while driving.

Window control system: Used to detect the opening and closing status of the windows and trigger the corresponding electric window control.

Seat adjustment system: Used to monitor the status of the seat adjustment button to adjust the seat position.

Button and switch control: Used to monitor the status of buttons and switches on the instrument panel and trigger corresponding control operations.

Environmental adaptability: Micro switches on automobile PCB control boards usually need to have good environmental adaptability, including resistance to vibration, dust proof, waterproof and high/low temperature resistance. This is because the vehicle may be exposed to harsh road and weather conditions while driving.