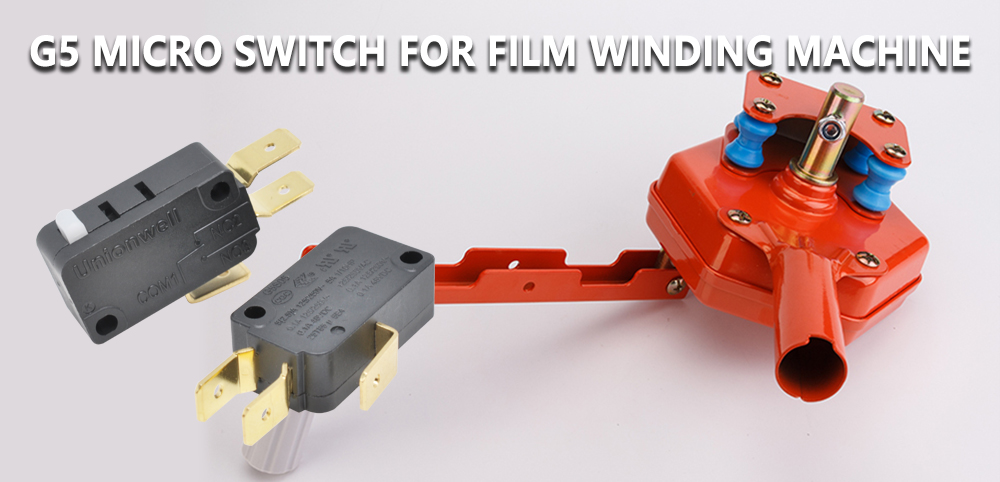

Overview of the film winder G5 micro switch

The G5 micro switch of the film rolling machine is a switch device used to control the film rolling equipment. Film rollers are widely used in greenhouses, greenhouses, farmland and other places to control the expansion and contraction of film materials such as sunshade nets and insulation films to adjust environmental conditions such as temperature, humidity and light in the greenhouse. G5 micro switch plays the role of detecting and transmitting signals in the film rolling system to ensure the accuracy and reliability of the film rolling operation.

Micro switches work based on the principle of mechanical contacts. When the actuator (such as motor) of the film rolling machine moves to a specific position, the G5 micro switch is triggered to generate an electrical signal. This signal can be used to control the start, stop or change of movement direction of the film rolling equipment. Micro switches usually consist of a mechanical arm, contacts, springs and housings. The robotic arm can be designed into different shapes as needed to adapt to specific installation environments and triggering conditions.

G5 micro switches are usually installed on the moving parts of the film winder, such as the drum or support beam. When these parts move to a specific position, the microswitch is triggered. The micro switch of the film rolling machine needs to have certain waterproof, dustproof and corrosion resistance properties, because the film rolling equipment is usually outdoors and is easily affected by the environment.

The electrical characteristics of G5 micro switch include rated current, rated voltage and switch life. These characteristics need to be selected according to the specific requirements of the roll film equipment. Micro switches have adjustable trigger position or sensitivity to meet the needs of different application scenarios.

The G5 microswitch of the film roller plays an important role in automated agricultural and greenhouse equipment. By accurately detecting and transmitting signals, it ensures the accuracy of the film rolling operation, improves production efficiency, and ensures a good growth environment in the greenhouse.

The role of G5 micro switch in film rolling machine

The G5 microswitch plays a key role in the film rolling machine. It is mainly used to detect and control the movement status of the film rolling system to ensure the accuracy and reliability of the film rolling operation. The G5 microswitch plays multiple roles in the film rolling machine, such as position detection, motion control, protection functions and system security. It provides important support for the normal operation and automatic control of the film rolling system.

-

Position detection of film rolling machine

The G5 microswitch is mounted on the moving parts of the film reel, such as the drum or support beam. When these parts move to a specific position, the microswitch is triggered. This provides accurate detection of the film winder position, ensuring that the film winding operation can be stopped or started precisely when required.

The micro switch of the film reel usually consists of a switch body made of metal material and a movable swing arm. The switch body is fixed on the bracket of the film rolling machine, and the swing arm is connected with the drawstring of the film rolling machine. When a certain degree of tension from the pull cord acts on the swing arm, the swing arm will be bent and exerted on the switch body, thereby triggering the switch.

-

Motion control of film rolling machine

The trigger signal of the G5 micro switch is used to control the movement of the film rolling machine. By cooperating with other electrical components (such as motors, relays, etc.), the G5 micro switch can trigger the film roll to start, stop or change the direction of movement, thereby achieving precise control of the film roll system.

The microswitch of the film rolling machine needs to be connected to the electrical control system of the film rolling machine. Normally, one end of the switch is connected to the power supply, and the other end is connected to the drive unit of the film winder. When the contacts connect or disconnect the circuit, the film rolling machine can be controlled through the electrical control system.

-

Protective function of film rolling machine

The G5 micro switch can be used to set the limit position. Once the film roller moves to the set boundary position, the micro switch will trigger and stop further movement, thereby preventing excessive film rolling or damage to the equipment. Due to the use of contacts and switch bodies made of metal materials, they have good wear resistance and conductive properties. Therefore, the film winder micro switch has a long service life and high reliability.

-

System safety of film rolling machine

G5 micro switch plays an important safety role in the roll film system. By accurately detecting the position and status of the film winder, the G5 micro switch can ensure that the system operates within a safe range and prevent unexpected failure or damage.

The microswitch of the film reel is usually fixed on the film reel bracket using screws or welding, which is easy to install. At the same time, if the switch fails or needs to be replaced, it can be maintained with simple removal and installation steps.

-

Automatic control of film rolling machine

The G5 microswitch is a key component of the automated film rolling system. By combining with other automation components (such as sensors, controllers, etc.), the G5 micro switch can realize intelligent control of the film rolling machine, automatically adjust the film rolling operation according to environmental conditions and preset parameters, and improve production efficiency.

The microswitch of the film rolling machine works closely with the electrical control system to realize automated control and operation. By setting appropriate control strategies and parameters, the film rolling machine can be automatically opened and closed to improve work efficiency.

The working principle of the micro switch of the film rolling machine

The film roll microswitch is a common control device that is widely used in agriculture, greenhouses and other fields to control the operation of the film roll. The film roller is a device used to open and close the greenhouse covering (usually plastic film). Automatic control and operation can be achieved through the micro switch of the film roller.

There is also one or more contacts inside the microswitch of the film winder for transmitting electrical signals. Contacts are usually made of metal materials with good electrical conductivity. When the swing arm is pulled, the contacts make or break the circuit.

When the film rolling machine is in a closed state, the pull cord is in a relaxed state, the swing arm is not under tension, the switch contacts are disconnected, and no current is conducted. When the film roll needs to be rolled up, the electrical control system will apply tension on the pull cord, which is transmitted to the swing arm to bend and exert pressure on the switch body. At this time, the switch contact is closed, conducts current, and sends a signal to the drive unit of the film roller to start working and open the film roller. When it is necessary to close the film roller, the electrical control system stops exerting pulling force, the pull rope relaxes, and the swing arm returns to its normal position. At this time, the switch contact is disconnected, the current no longer flows, the drive unit stops working, and the film winding machine is closed.

The micro switch of the film rolling machine has a simple structure and small size, and can be adjusted according to different installation spaces. At the same time, the length of the switch swing arm can be adjusted to meet the needs of different pull cord lengths. The microswitch of the film rolling machine realizes the automatic control of the film rolling machine through the mechanical structure, contact design and circuit connection. It has the characteristics and advantages of flexibility, reliability, convenient installation and maintenance, and is widely used in greenhouses, agriculture and other fields, improving production efficiency and work efficiency.